Product

Contact Info

Hotline: +86-18000614657

E-mail: admin@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

Horizontal Type Wire Drawing Machine

- Commodity name: Horizontal Type Wire Drawing Machine

- 产品描述

-

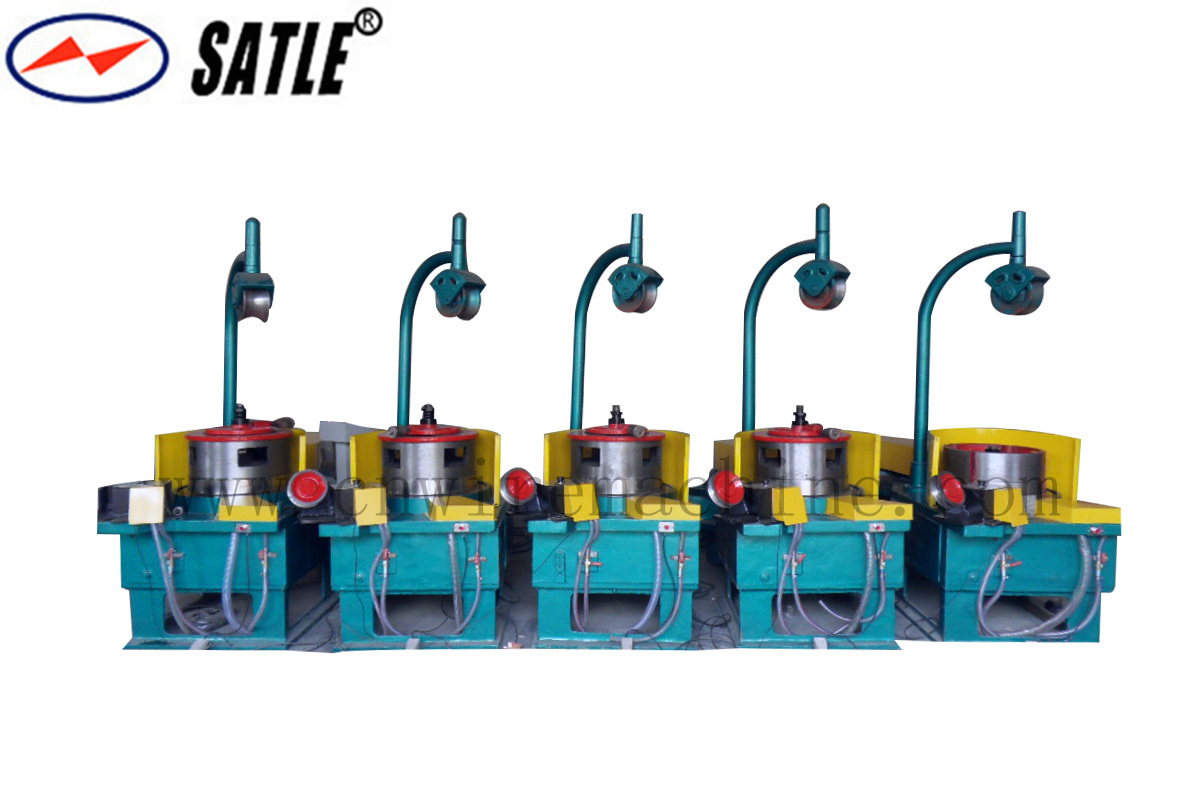

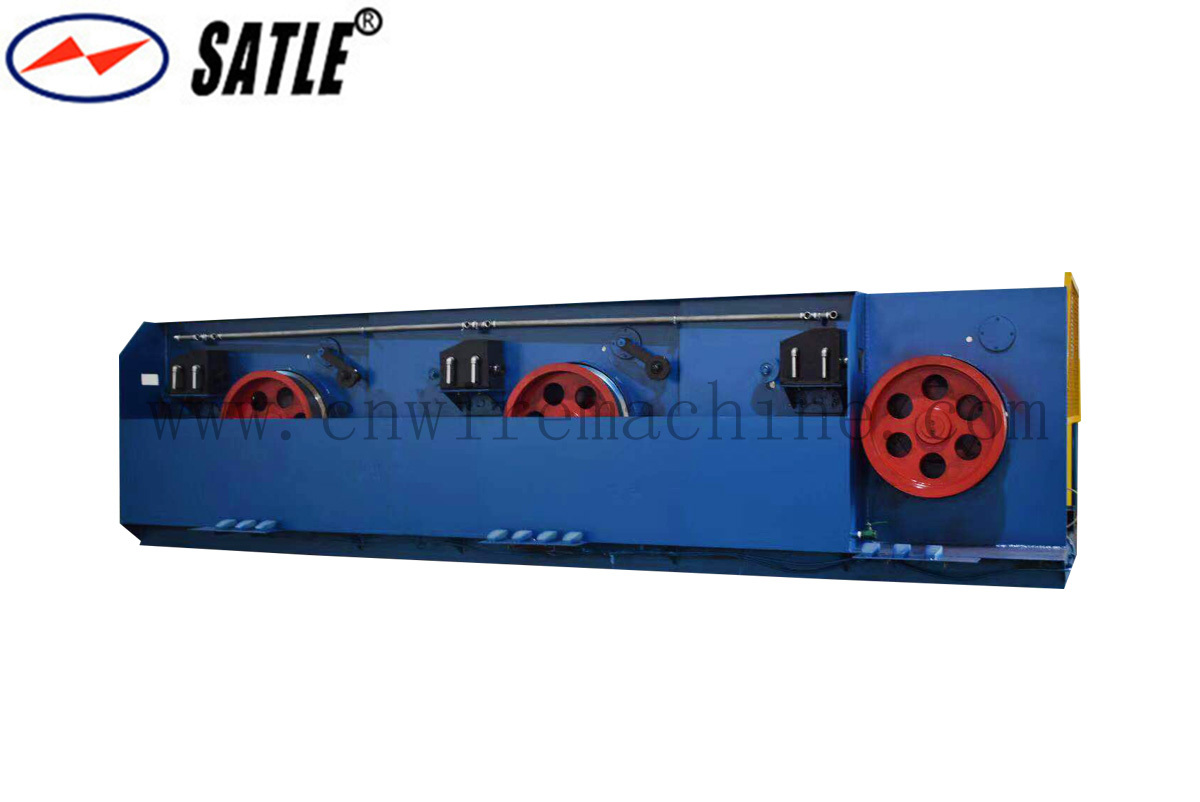

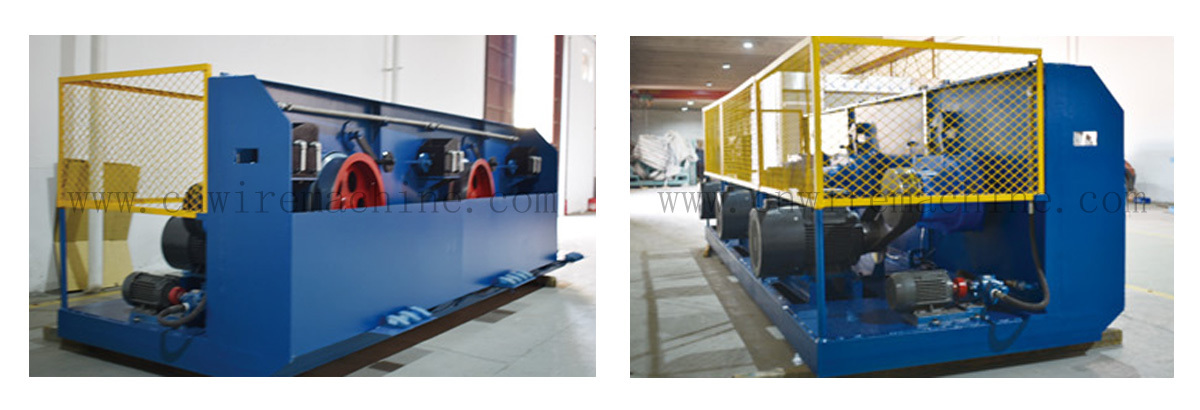

Product display

The Horizontal Wire Drawing Machine is a specialized industrial equipment used in the metalworking industry for the process of wire drawing. This machine is designed to efficiently reduce the diameter of metal wires while enhancing their surface finish and mechanical properties. It operates horizontally, allowing the wire to be drawn through a series of dies and lubricated with coolant or lubricant to minimize friction and heat generation. The Horizontal Wire Drawing Machine is widely utilized in various applications, including the production of electrical wires, steel wires, welding wires, and other types of metallic wires.

The Horizontal Type Wire Drawing Machine is a specialized equipment designed for the drawing or pulling of wires in a horizontal direction. This machine is widely used in industries such as steel, wire production, and cable manufacturing. It is capable of processing various types of metal wires, including copper, aluminum, stainless steel, and more. The main function of the Horizontal Type Wire Drawing Machine is to reduce the diameter of the wire while increasing its length. The machine achieves this by pulling the wire through a series of dies or molds, which progressively decreases its cross-sectional area. This process is known as wire drawing and is essential for achieving smoother and more uniform wire surfaces. By removing imperfections and defects, the machine allows for improved wire quality and enhanced mechanical properties. The Horizontal Type Wire Drawing Machine is equipped with various features to ensure efficient wire processing. These include adjustable drawing speeds, automatic wire tension control, lubrication systems, and precision die alignment mechanisms. Additionally, safety measures such as emergency stop buttons and protective covers are incorporated to minimize risks during operation. Overall, the Horizontal Type Wire Drawing Machine plays a crucial role in the wire manufacturing industry, enabling the production of high-quality wires used in various applications.

One of the key features of the Horizontal Wire Drawing Machine is its ability to accommodate different wire diameters and materials. This machine typically consists of multiple drawing dies arranged in a series, each with a progressively smaller diameter. As the wire passes through these dies, it undergoes plastic deformation, reducing its cross-sectional area and increasing its length. The Horizontal Wire Drawing Machine can handle a wide range of wire sizes, from thick rods to fine wires, and it supports various materials such as copper, aluminum, steel, and alloy wires.

The Horizontal Wire Drawing Machine offers several advantages in the wire manufacturing process. Firstly, it allows for precise control over the wire diameter, ensuring consistent quality and dimensional accuracy. Secondly, the wire's surface finish is improved, resulting in enhanced electrical conductivity, corrosion resistance, and overall mechanical strength. Additionally, this machine enables high production rates, making it suitable for large-scale wire manufacturing operations. The Horizontal Wire Drawing Machine is equipped with advanced automation features, including tension control systems, speed regulation, and real-time monitoring, ensuring efficient and reliable operation while minimizing downtime and material waste.

Product introduction

Suitable for drawing of copper, aluminium, stainless steel wire and flat wire.

Control System: PLC control, AC inverter motor, touch screen.

Product parameters

Our services

1、We not only provide customers with excellent solutions, related equipment and perfect services for steel wire production lines, but also provide customers with free technical services for steel wire production lines.

2、If you are in the production of steel wire or have any questions about the steel wire production line, please feel free to contact us Our solution and quotation will be sent to you soon with your special requirements.

3、Welcome to visit our factory and wire drawing line.

4、Engineers who can serve overseas machinery, free training on how to install and use machines, online support.

5、The cost of continuing maintenance after the warranty period expires is low.

Qualification certificate

Plant equipment

Exhibition visit

Freight logistics

Marketing network

Key words: