Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

PLC Wire straight and cut machine

- Commodity name: PLC Wire straight and cut machine

- 产品描述

-

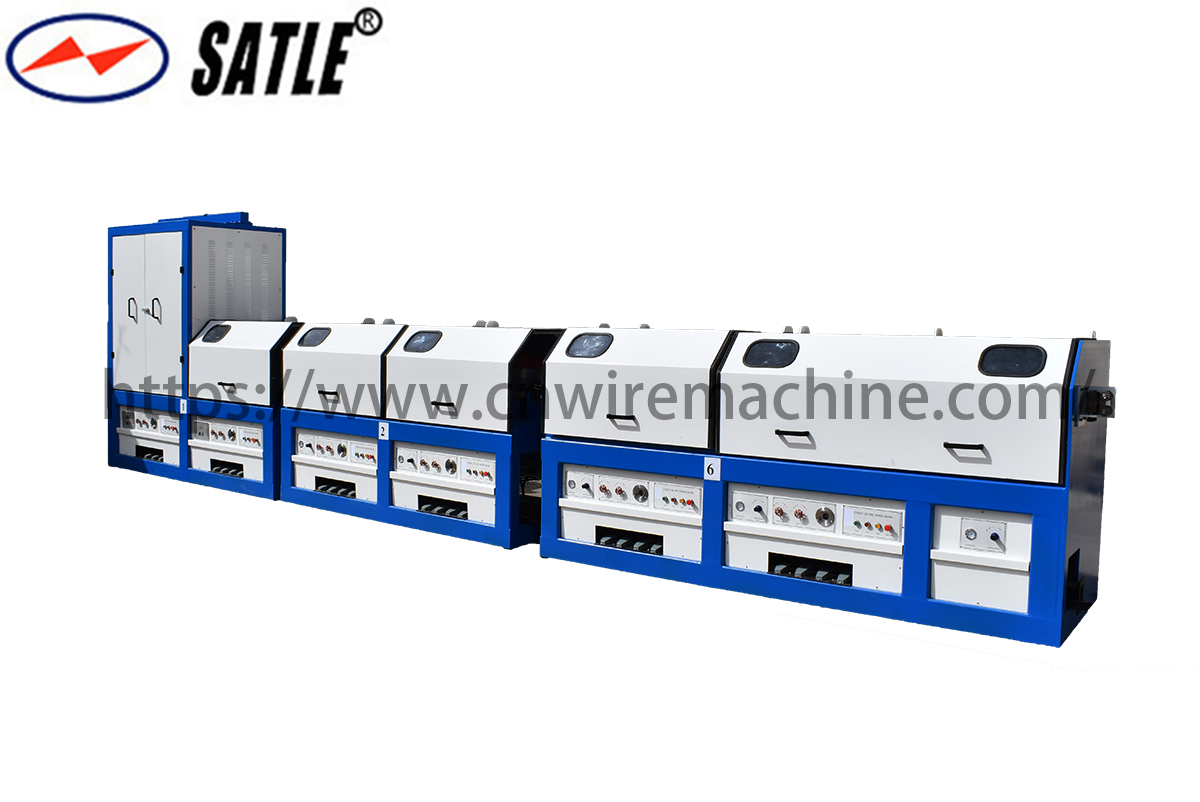

Product Overview

The SATLE Wire straight and cut machine is a composite machine integrating the functions of straightening and cutting, specially designed for straightening and length-setting cutting of metal materials (such as steel wire, iron wire, copper wire, etc.). Through high-precision dynamic compensation and non-destructive cutting technology, it ensures that the material straightness error is ≤0.1mm/m, and realizes burr-free and scratch-free cutting effect, which is the core equipment for metal processing industry to improve the efficiency and quality of finished products.

Product Display

Product details: Wire diameter: 3-8 mm Cut length: 700-6000 mm Length tollerance: ≤ ±1 mm Straighteness error: ≤ 2 mm/m Work Speed: 100-135 m/min Motor: 4.0-15 kw PLC System: Siemens Brand Application Fields

- Steel wire processing: for straightening and cutting of carbon steel wires to length.

- Stainless steel wire processing: for straightening and cutting of stainless steel wire.

- Hardware industry: for precision processing of metal wires.

FAQ

Q.1: Are you manufacturer or trading company?

▼ View More FAQ Questions

Q.2: Customized equipment solutions, what information do I need to provide?

Q.3: What payment methods do you support?

Q.4: How can I trust you and pay?

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

Q.6: Do you provide overseas installation and commissioning services?

Q.7: Can you build a machine based on my design or prototype?

Q.8: How does your factory perform quality control?

Q.9: How can I trust that you tested and commissioned the machine before shipping?

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

Q.11: What should I do if I am just starting my business?

Q.12: Can I visit your factory and inspect the machines on site?

--- Click the blue button to collapse ---

Our services

Qualification certificate

Customer Use/Visit SATLE Wire Drawing Equipment

SATLE Machinery Exhibition

SATLE Wire Drawing Machine Are Shipping

Key words:

PLC Wire straight and cut machine supplier

wire straight and cut machine factory