Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

25mm Steel bar inverted type drawing machine shelling and derusting integrated

- Commodity name: 25mm Steel bar inverted type drawing machine shelling and derusting integrated

- 产品描述

-

Product Overview

The Inverted Vertical Wire Drawing Machine is mainly used for drawing high carbon steel wire, stainless steel wire, various alloy wires and other cold heading quality wires with coarse size and high coil weight. This machine can improve efficiency to a great extent because drawing is carried out from one wire coil to another, and the drawn wire is wound directly on the coil wire stand which is continued in the factory as it is or shipped in large coils.

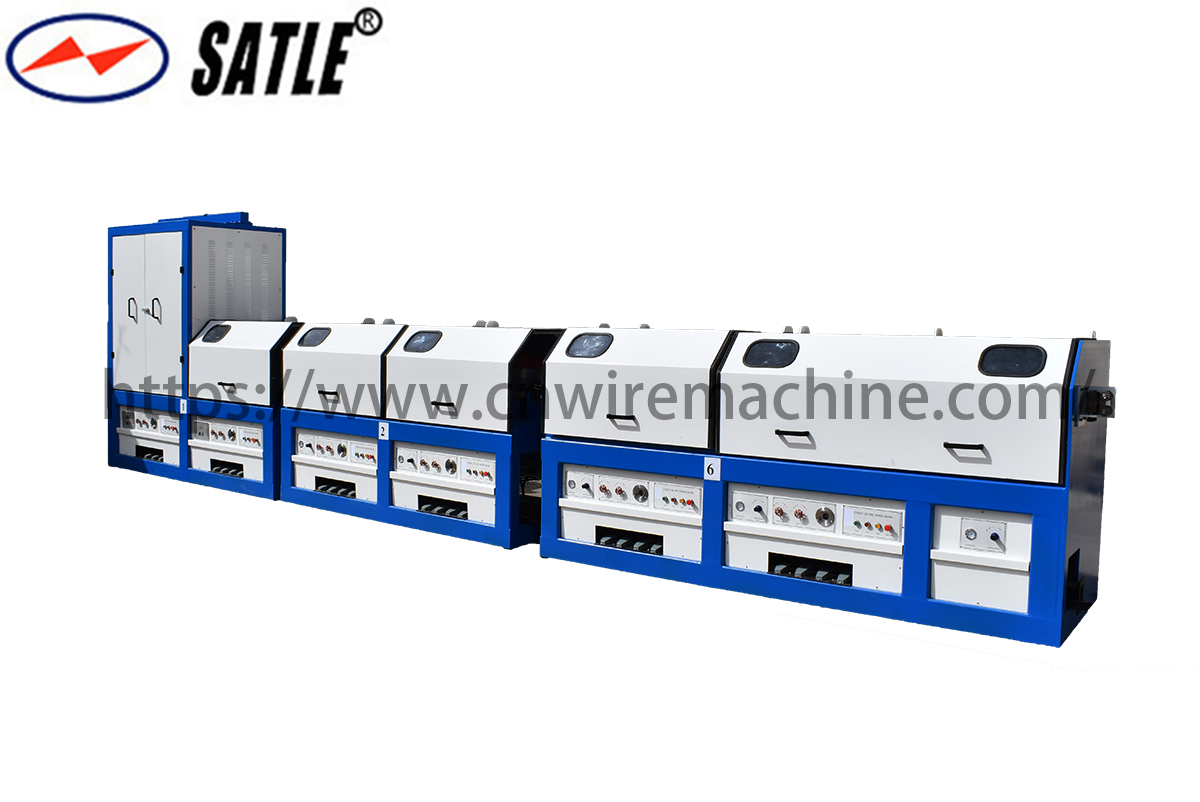

Product Display

Fields of application

- Construction industry: for the production of high-strength steel wires for reinforced concrete structures.

- Manufacturing industry: metal wires for the production of mechanical parts.

- Electrical industry: copper wire and aluminum wire for manufacturing wires and cables.

Product parameters

Model LD-800

LD-1000

LD-1200

Max Inlet Dia(mm) 12

18

25

Power(kw) 37

45

55

NO. of drafts 1

1

1

Speed Range (mtrs./min.) 30-100

15-55

10-40

Max. Coil Weight (kgs.) 2000

2500

2500

FAQ

Q.1: Are you manufacturer or trading company?

▼ View More FAQ Questions

Q.2: Customized equipment solutions, what information do I need to provide?

Q.3: What payment methods do you support?

Q.4: How can I trust you and pay?

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

Q.6: Do you provide overseas installation and commissioning services?

Q.7: Can you build a machine based on my design or prototype?

Q.8: How does your factory perform quality control?

Q.9: How can I trust that you tested and commissioned the machine before shipping?

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

Q.11: What should I do if I am just starting my business?

Q.12: Can I visit your factory and inspect the machines on site?

--- Click the blue button to collapse ---

Our services

Qualification certificate

Customer Use/Visit SATLE Wire Drawing Equipment

SATLE Machinery Exhibition

SATLE Wire Drawing Machine Are Shipping

Key words:

Inverted Wire Drawing Machine

inverted wire drawing machine manufacturer

inverted wire drawing machine factory

inverted wire drawing machine supplier

inverted wire drawing machine exporter