Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

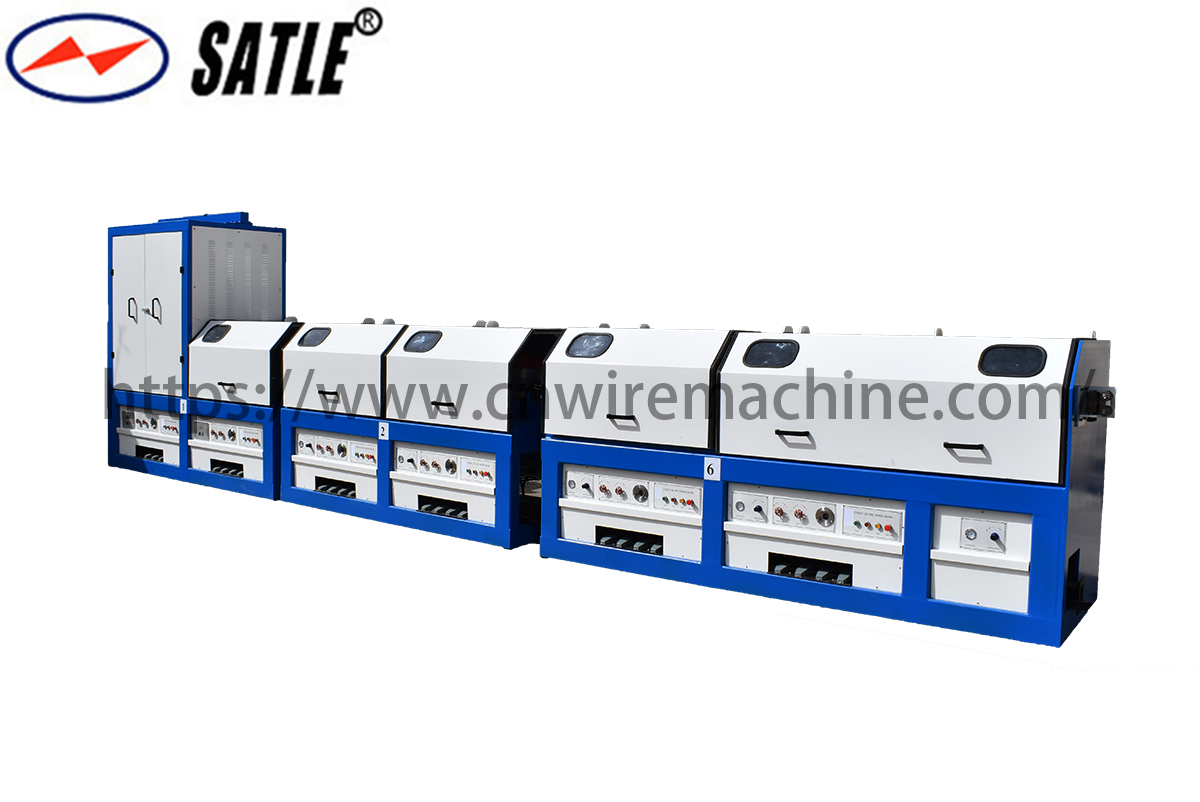

LZ-600 Stainless Steel Dry Wire drawing machine

- Commodity name: LZ-600 Stainless Steel Dry Wire drawing machine

- 产品描述

-

Product display

Product introduction

The SATLE LZ-600 stainless steel wire drawing machine is suitable for low, medium and high carbon steel wire drawing. According to different wire materials, applications and wire diameters, different types of wire drawing machines are selected.

The equipment is driven by AC frequency conversion motor and hard tooth surface gear, Siemens PLC digital control, touch screen human interface, energy saving and high efficiency.

Reel: cast steel ZG45, surface sprayed with tungsten carbide HRC60, inside is slit water cooling. There are operation buttons in front of each roll.

Transmission mode: gear transmission

Brake: The material is ductile iron. Features pneumatic disc brakes that bring the machine to an immediate stop

The SATLE LZ-600 Stainless Steel Wire drawing machine offers several advantages in the wire manufacturing process. Firstly, it allows for precise control over the wire diameter, ensuring consistent quality and dimensional accuracy. Secondly, the wire's surface finish is improved, resulting in enhanced electrical conductivity, corrosion resistance, and overall mechanical strength. Additionally, this machine enables high production rates, making it suitable for large-scale wire manufacturing operations. The Stainless Steel wire processing machine is equipped with advanced automation features, including tension control systems, speed regulation, and real-time monitoring, ensuring efficient and reliable operation while minimizing downtime and material waste.

Product parameters

Model: LZ-350 LZ-400 LZ-560 LZ-600 LZ-620 LZ-700 Wire drawing equipment For: Small drawing equipment Small size steel wire Low carbon steel wire Medium size drawing equipment High carbon steel wire Heavy drawing equipment Winding drum diameter: 350 400 560 600 620 700 Max Inlet Dia(mm): 3.5 4.2 6.5 8.0 8.0 12.0 Min Outlet Dia(mm): 0.6 0.8 1.4 1.6 2.0 3.0 Power(kw): 7.5-11 11-15 18.5-30 22-37 30-45 30-55 NO. of drafts: 12 12 12 12 10 10 Pay-off: Spooler pay-off, High frame pay-off, Horizontal pay-off, can pay-off without stop working

Take-up: Spooler take-up, Coiler take-up, Inverted pay-off, can take-up without stop working

Customization: ✔️ ✔️ ✔️ ✔️ ✔️ ✔️

FAQ

Q.1: Are you manufacturer or trading company?

A.1: We are a manufacturer.

Q.2: Customized equipment solutions, what information do I need to provide?

A.2: Wire material, inlet and outlet wire diameters, spool size, application, and your other requirements.

Q.3: What payment methods do you support?

A.3: T/T, L/C, Western union, cash, etc.

Q.4: How can I trust you and pay?

A.4: (1) We are a supplier audited by SGS and hold their certificate. We also have CE certificates from EU countries, they recognize us as the original manufacturer and meet their standards.

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

A.5: Don't worry, we will guide you through the import procedures or you can ask your local agent for help.

Q.6: Do you provide overseas installation and commissioning services?

A.6: We provide overseas machine installation and worker training services, and we also provide remote debugging support when the equipment encounters problems later.

Q.7: Can you build a machine based on my design or prototype?

A.7: Yes, we have an experienced technical team that can develop the most suitable design and production program for the machine you book.

Q.8: How does your factory perform quality control?

A.8: There is zero tolerance for poor quality products. Quality control is in accordance with SGS and ISO 9001 standards. Each machine must be tested and commissioned before it is packaged for shipment.

Q.9: How can I trust that you tested and commissioned the machine before shipping?

A.9: (1) We will record a test video for you and provide you with all necessary photos.

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

A.10: We provide online technical support and overseas service by skilled technicians.

Q.11: What should I do if I am just starting my business?

A.11: Please contact us, we provide free pre-sales consultancy service. In addition, we can help you with material procurement and worker training.

Q.12: Can I visit your factory and inspect the machines on site? What should I bring when visiting the factory?

A.12:We are a manufacturer and welcome customers to visit us. For special product design, we suggest you to bring some samples which you can test with our machines on site.

Our services

Qualification certificate

Plant equipment

Exhibition visit

Freight logistics

Marketing network

Key words:

Wire making machine

Wire processing machine

Wire drawing machine price