Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

Hydraulic high style scaling payoff machine

Highly efficient and stable, designed for metal wire payoffs.

- Commodity name: Hydraulic high style scaling payoff machine

Category:

- 产品描述

-

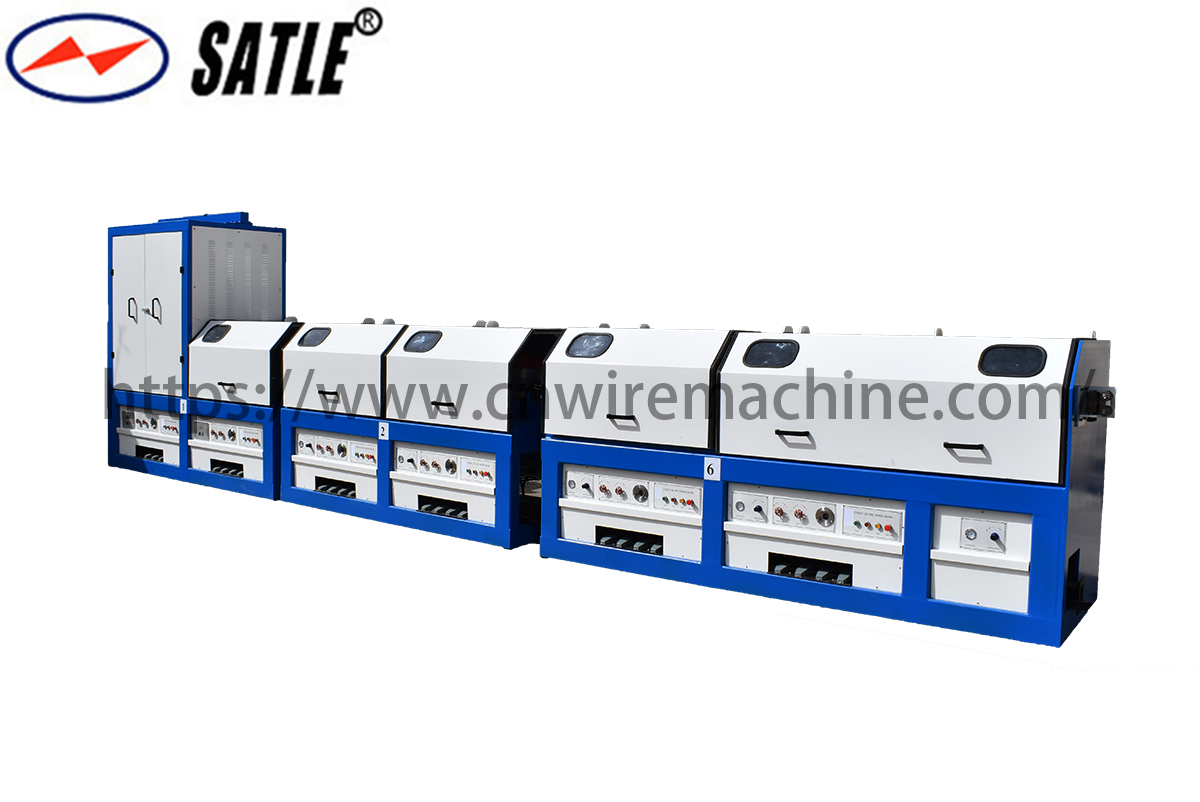

Product Overview

The Hydraulic high style scaling payoff machine is a highly efficient machine designed for continuous payoff of medium carbon, mild and stainless steel wire. With its pneumatic tilt-threading design, high-speed payoff capability and intelligent inspection features, this machine is ideal for the wire processing industry because of its ability to significantly increase productivity.

Core features

1. High-efficiency continuous payoff

- Supports head-to-tail butt welding of coils, realizing sustainable operation and reducing downtime.

- Unwinding speed: up to 5.0 meters/second, depending on model and height.

2. Pneumatic tilt threading design

- Ergonomic design for easy operation and reduced manual intervention.

- Tilt lever design facilitates coil loading and enhances work efficiency.

3. Customized height and specifications

- Height customization: 5m to 12m, adapting to different production environments.

- Wire inlet diameter: 2.0mm to 8mm, to meet diversified wire needs.

4. Intelligent inspection function

- Equipped with wire guide cage on the top, both wire guide and jam detector functions.

- Equipped with wire jamming switch and wire breakage sensor, real-time monitoring of unwinding status to ensure production continuity.

5. Durable stripping machine

- The stripping machine adopts Cr12Mov stripping wheel, which is durable and suitable for storing messy or long time wires.

Technical specifications

Attributes Specifications Customizable Payoff speed 3-5 m/s ✅ Height 5-12 m ✅ Inlet diameter 2-8 mm ✅ Main Advantages

- Efficient and continuous: supports butt welding of coil head and tail, reducing downtime.

- Convenient operation: Pneumatic tilting threading design is ergonomic and reduces the difficulty of manual operation.

- Intelligent detection: wire guide cage, jam switch and wire breakage sensor ensure stable and reliable unwinding process.

- Durable package: Cr12Mov stripping wheel, extending the service life of the equipment and reducing maintenance costs.

- Flexible customization: Support height and wire specification customization to meet diversified production needs.

Application Fields

- Wire and cable industry: for copper wire, aluminum wire and other conductors payoff operation.

- Construction industry: for the release of steel bars, prestressing steel wire and other building materials.

- Hardware industry: for steel wire, stainless steel wire and other metal wire processing.

FAQ

Q.1: Are you manufacturer or trading company?

We are a manufacturer.

▼ View More FAQ Questions

Q.2: Customized equipment solutions, what information do I need to provide?

Wire material, inlet and outlet wire diameters, spool size, application, and your other requirements.

Q.3: What payment methods do you support?

T/T, cash, etc.

Q.4: How can I trust you and pay?

(1) We are a supplier audited by SGS and hold their certificate. We also have CE certificates from EU countries, they recognize us as the original manufacturer and meet their standards.

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

Don't worry, we will guide you through the import procedures or you can ask your local agent for help.

Q.6: Do you provide overseas installation and commissioning services?

We provide overseas machine installation and worker training services, and we also provide remote debugging support when the equipment encounters problems later.

Q.7: Can you build a machine based on my design or prototype?

Yes, we have an experienced technical team that can develop the most suitable design and production program for the machine you book.

Q.8: How does your factory perform quality control?

There is zero tolerance for poor quality products. Quality control is in accordance with SGS and ISO 9001 standards. Each machine must be tested and commissioned before it is packaged for shipment.

Q.9: How can I trust that you tested and commissioned the machine before shipping?

(1) We will record a test video for you and provide you with all necessary photos.

(2) We welcome you to visit our factory and test the machine yourself.

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

We provide online technical support and overseas service by skilled technicians.

Q.11: What should I do if I am just starting my business?

Please contact us, we provide free pre-sales consultancy service. In addition, we can help you with material procurement and worker training.

Q.12: Can I visit your factory and inspect the machines on site?

Welcome customers to visit us. For special product design, we suggest you to bring some samples which you can test with our machines on site.

--- Click the blue button to collapse ---

Our services

All-round solution: provide high quality steel wire production line equipment, technical support and perfect service, free customized production line solution for you.

Quick Response: If you have any wire production needs or questions, please contact us, we will quickly provide solutions and quotations according to your requirements.

Factory visit: Welcome to visit our factory and wire drawing line to witness our strength.

Global support: provide engineer service for overseas customers, free training on equipment installation and use, and support online technical guidance.

Low-cost maintenance: Provide cost-effective maintenance services even after the warranty period to ensure the long-term stable operation of the equipment.

Qualification certificate

Customer Use/Visit SATLE Wire Drawing Equipment

SATLE Machinery Exhibition

SATLE Wire Drawing Machine Are Shipping

Key words:

OVERHEAD PAY-OFF Machine

Efficient and continuous

Intelligent detection