Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

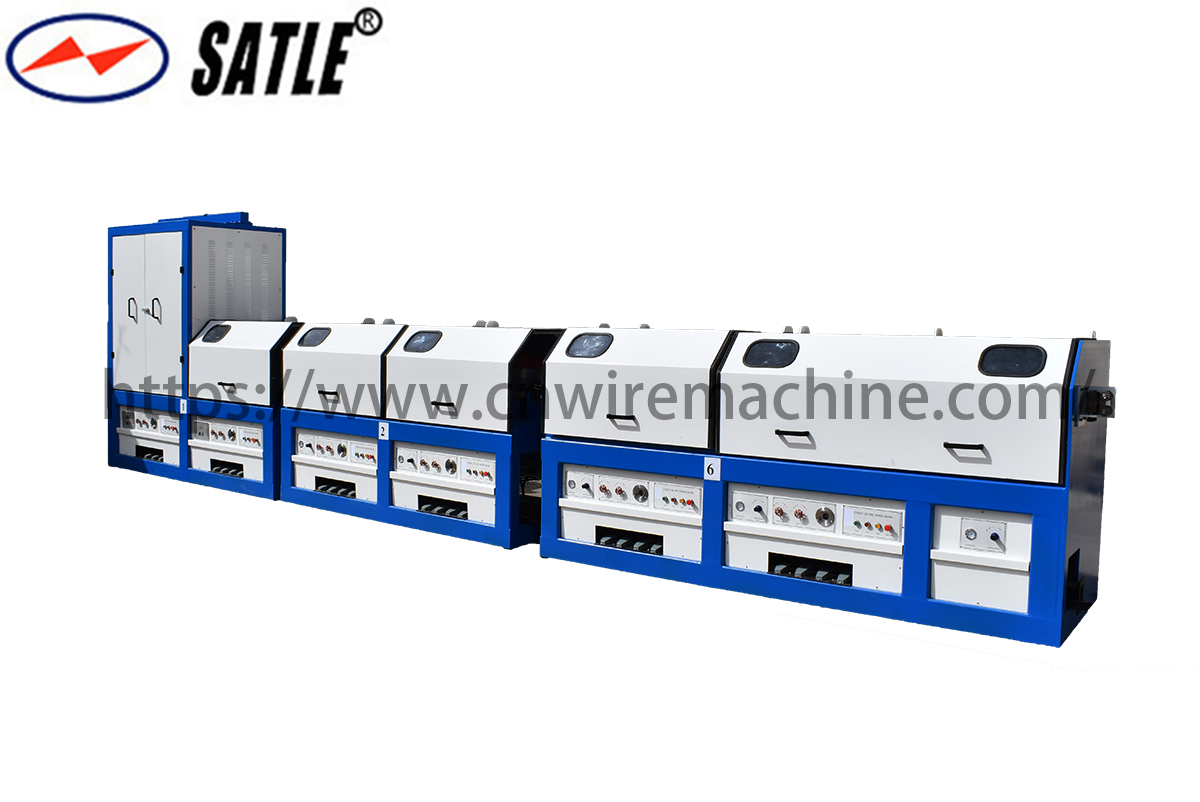

Horizontal Type Aluminum Wire Drawing Machine

- Commodity name: Horizontal Type Aluminum Wire Drawing Machine

- 产品描述

-

Product Overview

Horizontal Type Aluminum Wire Drawing Machine is the key equipment in metal wire processing, cold drawing of aluminum wire through multi-pass mold, reduce wire diameter and improve mechanical strength, surface finish and conductivity, widely used in wire and cable, hardware manufacturing and other fields. Among the many types of wire drawing machines, the horizontal wire drawing machine has become the ideal choice for aluminum wire drawing by virtue of its large drawing force, stability and ease of operation, especially suitable for coarse aluminum wire, small quantities of multiple specifications and low and medium-speed production scenarios.

Product Display

Core advantages

1. Large drawing force, stable handling of coarse aluminum wire

- Drawing force ≥10kN, able to handle Φ8mm-Φ20mm thick aluminum wire stably, avoiding the risk of wire breakage.

- Graded drawing by molds: Gradually drawing to the target diameter through multiple molds to ensure the uniformity and surface quality of the wire.

2. Low center of gravity design, stable operation

- Horizontal structure with low center of gravity, low vibration and high stability during operation, suitable for long time continuous operation.

3. Open design, convenient operation

- Convenient loading, mold changing and maintenance: open structure design simplifies the operation process, especially suitable for small batch and multi-specification aluminum wire production needs.

- Strong adaptability: molds and parameters can be quickly adjusted according to different specifications of aluminum wire to improve production efficiency.

The Value of Horizontal Wire Drawing Machines in Aluminum Wire Drawing

1. Adaptation to coarse aluminum wire processing

- The large drawing force and stability of the horizontal wire drawing machine enable it to efficiently process coarse aluminum wire and meet the demand for high-strength aluminum wire in the wire and cable industry.

2. Enhance wire quality

- Through multi-stage mold drawing, it ensures uniform wire diameter and smooth surface, and improves electrical conductivity and mechanical strength.

3. Flexible response to small-lot multi-specification production

- The open design and quick mold change function enable it to flexibly respond to the demand for small-lot, multi-specification aluminum wire production and reduce production costs.

4. Reduce the risk of wire breakage

- Stable pulling force and low center of gravity design effectively reduce the risk of wire breakage, reduce material waste and equipment downtime.

Main Advantages

- High efficiency and stability: large drawing force and low center of gravity design ensure stable and efficient drawing process of coarse aluminum wire.

- Convenient operation: open structure, easy loading, mold change and maintenance, adapt to small batch and multi-specification production.

- Enhance quality: Multi-pass mold drawing ensures wire uniformity and surface finish.

- Reduce cost: Reduce the risk of wire breakage, material waste and equipment downtime.

Application Fields

- Wire and cable industry: for the drawing of high-strength aluminum wires.

- Hardware manufacturing industry: for precision processing of aluminum wires.

- Construction industry: for structural reinforcement and connection of aluminum wires.

Why choose our horizontal aluminum wire drawing machine?

Shijiazhuang Satle Machinery Manufacturing Co., Ltd. specializes in the research, development and manufacturing of aluminum wire processing equipment with more than 20 years of industry experience. Our Horizontal Aluminum Wire Drawing Machine has won the trust of customers all over the world with its high performance, high stability and customer-oriented design concept.

FAQ

Q.1: Are you manufacturer or trading company?

A.1: We are a manufacturer.

Q.2: Customized equipment solutions, what information do I need to provide?

A.2: Wire material, inlet and outlet wire diameters, spool size, application, and your other requirements.

Q.3: What payment methods do you support?

A.3: T/T, L/C, Western union, cash, etc.

Q.4: How can I trust you and pay?

A.4: (1) We are a supplier audited by SGS and hold their certificate. We also have CE certificates from EU countries, they recognize us as the original manufacturer and meet their standards.

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

A.5: Don't worry, we will guide you through the import procedures or you can ask your local agent for help.

Q.6: Do you provide overseas installation and commissioning services?

A.6: We provide overseas machine installation and worker training services, and we also provide remote debugging support when the equipment encounters problems later.

Q.7: Can you build a machine based on my design or prototype?

A.7: Yes, we have an experienced technical team that can develop the most suitable design and production program for the machine you book.

Q.8: How does your factory perform quality control?

A.8: There is zero tolerance for poor quality products. Quality control is in accordance with SGS and ISO 9001 standards. Each machine must be tested and commissioned before it is packaged for shipment.

Q.9: How can I trust that you tested and commissioned the machine before shipping?

A.9: (1) We will record a test video for you and provide you with all necessary photos.

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

A.10: We provide online technical support and overseas service by skilled technicians.

Q.11: What should I do if I am just starting my business?

A.11: Please contact us, we provide free pre-sales consultancy service. In addition, we can help you with material procurement and worker training.

Q.12: Can I visit your factory and inspect the machines on site? What should I bring when visiting the factory?

A.12:We are a manufacturer and welcome customers to visit us. For special product design, we suggest you to bring some samples which you can test with our machines on site.

Our services

Qualification certificate

Plant equipment

Exhibition visit

Freight logistics

Marketing network

Key words:

Horizontal Wire Drawing Machine

Aluminum Wire Drawing Machines