Product

Contact Info

Hotline: +86-18831168296

E-mail: Info@cnwiremachine.com

Add: Gaoqian West Street, Sijiazhuang Town, Luquan District, Shijiazhuang City, Hebei Province

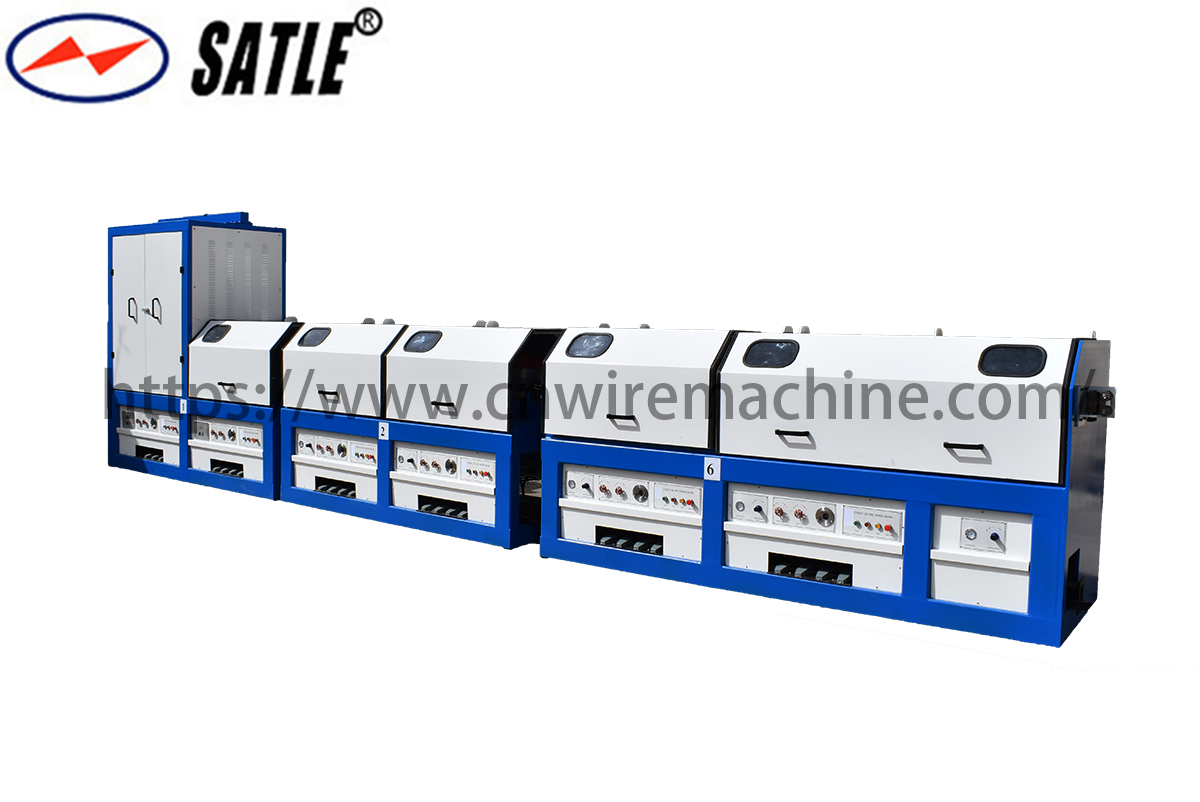

3-8 mm Steel Wire Straightening and Cutting Machine

- Commodity name: 3-8 mm Steel Wire Straightening and Cutting Machine

- 产品描述

-

Product Overview

SATLE automatic steel wire straightening and cutting machine is an industrial precision processing equipment developed with advanced electromechanical control technology, specially designed for the high-precision straightening and fixed-length cutting of 3-8mm cold-rolled round steel, cold-rolled ribbed steel bar, ribbed wires, reinforcing bars, and various other metal materials. Adopting Siemens PLC and touch screen integrated control system, this industrial steel wire straightener cutter realizes digital and precise adjustment of all processing parameters, with a straightening and cutting speed of 100-120m/min and a cutting length adjustable range of 700-6000mm. It strictly controls the length tolerance within ≤±1mm and the straightness error within ≤2mm/m, fully meeting the processing standards of industrial mass production. The equipment is optimized for mechanical structure and layout, with core transmission components and electrical systems selected in accordance with international industrial specifications. It features stable continuous operation, simple operation and convenient daily maintenance, and is a professional steel wire straightening and cutting equipment that can be seamlessly integrated into the standardized production lines of metal processing, construction and automotive manufacturing industries.

Core Points

1.High-speed Efficient Processing: The 100-120m/min high-speed steel wire straightening and cutting adapts to large-batch industrial production needs, greatly improving the overall processing efficiency of the production line.

2.Industrial Precision Cutting: Equipped with Siemens PLC + touch screen control system, the 3-8mm steel wire straightening and cutting machine supports precise adjustment of 700-6000mm cutting length, with length tolerance ≤±1mm and straightness error ≤2mm/m, ensuring high processing consistency.

3.Stable and Powerful Power: Configured with 15kW straightening motor and 4.0kW cutting motor, the industrial metal wire straightener cutter provides strong and continuous power output, ensuring stable operation under long-term working conditions.

4.Safe and User-friendly Operation: The equipment is equipped with simplified control panel, safety protective cover and parameter setting alarm reminder, which effectively guarantees the operation safety and reduces the professional training cost of operators.

5.Practical Auxiliary Design: Equipped with pay-off rack, steel wire protection rack and wire collection finishing device, the automatic steel wire processing equipment realizes stable pay-off and neat wire collection, optimizing the whole processing process of steel wire from feeding to finished product output.Technical Parameters

Parameter Type Specification Details Applicable Wire Diameter 3-8mm Cutting Length Range 700-6000mm (Precisely adjustable on demand) Length Tolerance ≤±1mm Straightness Error ≤2mm/m Straightening & Cutting Speed 100-120m/min Straightening Motor Power 15kW Cutting Motor Power 4.0kW Control System Siemens PLC + Touch Screen, with precise control and operation alarm reminder function Auxiliary Devices Pay-off rack, steel wire protection rack, wire collection finishing device

Application

1.Construction Industry: Special for steel wire straightening and cutting for reinforced concrete structures, providing high-precision processed steel bars and steel wires for building construction, bridge engineering and other infrastructure projects.

2.Automotive Manufacturing Industry: Realize precision steel wire processing for auto parts, providing customized length steel wire raw materials for the production of automotive structural parts and hardware accessories.

3.Metal Processing Industry: Adapt to the batch steel wire straightening and cutting for metal fabrication, supporting the pre-processing of steel wire for welding, metal mesh making and structural part processing.

4.Hardware Manufacturing Industry: Provide fixed-length steel wire cutting and straightening service for the production of various hardware products, ensuring the dimensional accuracy of raw materials and improving the qualification rate of finished products.

FAQ

Q.1: Are you manufacturer or trading company?

▼ View More FAQ Questions

Q.2: Customized equipment solutions, what information do I need to provide?

Q.3: What payment methods do you support?

Q.4: How can I trust you and pay?

(2) We are a member of “Made in China” “Alibaba” and always responsible for all customers.

(3) Please visit us and view our factory through online video and ask us for necessary documents.

Q.5: I have no experience in sourcing abroad. What should I do?

Q.6: Do you provide overseas installation and commissioning services?

Q.7: Can you build a machine based on my design or prototype?

Q.8: How does your factory perform quality control?

Q.9: How can I trust that you tested and commissioned the machine before shipping?

(2) We welcome you to visit our factory and test the machine yourself.

Q.10: How about your after-sales service?

Q.11: What should I do if I am just starting my business?

Q.12: Can I visit your factory and inspect the machines on site?

--- Click the blue button to collapse ---

Our services

Qualification certificate

Customer Use/Visit SATLE Wire Drawing Equipment

SATLE Machinery Exhibition

SATLE Wire Drawing Machine Are Shipping

Key words: